A brazing furnace is one of the most critical investments in a manufacturing facility where precision metal joining is essential. Whether you're in the aerospace, automotive, HVAC, electronics, or medical device industry, your brazing furnace plays a vital role in achieving high-quality, strong, and clean metal joints. To ensure optimal operation and maximize the furnace’s lifespan, regular maintenance and cleaning are non-negotiable.

Without proper care, even the most advanced brazing furnaces can experience performance degradation, inconsistent heating, contamination issues, or unplanned downtime. These problems can affect product quality, increase operational costs, and interrupt production schedules. Fortunately, with a well-structured maintenance and cleaning routine, you can extend the life of your brazing furnace and keep it running at peak performance.

In this guide, we’ll outline the most important practices for maintaining and cleaning your brazing furnace, helping you avoid costly repairs, reduce scrap rates, and ensure consistent, high-quality brazing results.

Understanding Why Maintenance Is Crucial for Brazing Furnaces

Unlike general heating equipment, brazing furnaces operate at extremely high temperatures, often in vacuum or controlled atmospheres like nitrogen or hydrogen. This environment requires precise temperature uniformity, cleanliness, and gas control. Over time, exposure to heat, flux residue, and metal fumes can:

Reduce heating efficiency

Contaminate internal surfaces

Damage insulation or heating elements

Cause vacuum or atmosphere leaks

Impact the quality of brazed joints

Routine maintenance keeps these issues at bay and preserves the precision capabilities of your furnace, ensuring every brazing cycle is consistent and reliable.

Daily Maintenance Tasks

Even the most complex equipment benefits from simple, daily checks. Incorporating these into your routine helps catch minor issues before they grow into major problems.

1. Visual Inspection

Check for signs of wear or damage on seals, gaskets, door latches, and viewing windows

Look for discoloration or debris on the furnace interior

Ensure that insulation is intact and no loose particles are floating inside the chamber

2. Monitor Operating Parameters

Record temperature readings, vacuum levels, and atmosphere gas pressures

Compare with normal baseline values to detect drift or irregularities

Ensure controllers and sensors are functioning correctly

3. Clean External Surfaces

Wipe down external panels, controls, and operator interfaces

Remove any dust or debris from air vents and electrical cabinets

Weekly Maintenance Checks

1. Inspect Heating Elements and Thermocouples

Ensure the heating elements are clean and not showing signs of oxidation or damage

Verify thermocouple readings are accurate by cross-checking with a calibrated reference device

Check for loose or corroded electrical connections

2. Verify Atmosphere Integrity

For vacuum furnaces: test vacuum pump performance, check for leaks, and inspect seals

For CAB furnaces: inspect gas supply lines, purge systems, and monitor gas purity levels

3. Check Moving Components

If your furnace includes conveyor belts or automated loading systems, ensure smooth movement and lubricate mechanical parts as needed

Tighten bolts or fasteners if necessary

Monthly Maintenance Practices

1. Deep Clean the Furnace Interior

Remove any buildup of metal spatter, flux residues, or particulate contaminants from the hot zone

Use vacuum-grade brushes and lint-free cloths to clean interior surfaces

Avoid using water or solvents unless specified by the furnace manufacturer

2. Clean or Replace Filters

Replace air filters in the control cabinet to prevent overheating of electronics

Clean gas purification filters, moisture traps, or oil mist separators if applicable

3. Lubricate Door Hinges and Seals

Ensure all moving parts on access doors are smooth and secure

Check seal elasticity and replace them if they have hardened or cracked

Quarterly and Annual Maintenance

1. Calibrate Sensors and Controllers

Conduct a full system calibration of thermocouples, PID controllers, and pressure gauges

Use certified calibration tools or service providers to ensure traceability and compliance

2. Inspect and Replace Insulation

High heat exposure can degrade insulation over time

Look for signs of shrinkage, cracking, or loss of integrity

Replace damaged insulation to maintain thermal efficiency and prevent hot spots

3. Test Safety Systems

Run functional tests on over-temperature alarms, gas leak detectors, and emergency shutdown switches

Ensure all safety systems comply with regulatory standards and are in working condition

4. Schedule a Professional Service

Arrange a comprehensive inspection by the furnace manufacturer or a certified technician

Perform leak tests, electrical diagnostics, and component stress analysis

Cleaning Tips Based on Furnace Type

Vacuum Brazing Furnace

Avoid introducing moisture or oil-based cleaners

Use dry cloths and approved vacuum-grade materials

Clean the diffusion pump and inspect the vacuum chamber’s interior for deposits

Controlled Atmosphere Brazing (CAB) Furnace

Clean nitrogen gas distribution lines to prevent clogging

Remove residue from ceramic rollers or conveyor belts

Inspect flame curtains and cooling zones for contamination

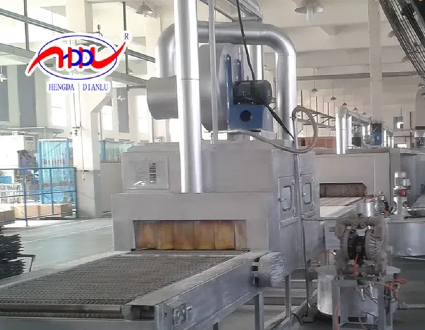

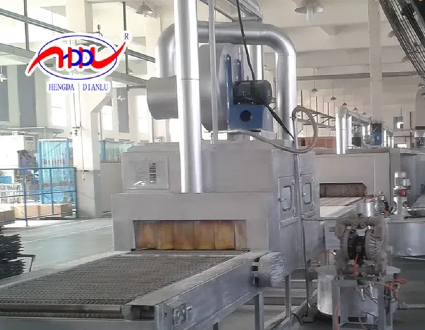

Continuous Mesh Belt Furnace

Clean mesh belts using wire brushes or dry compressed air

Ensure alignment of the belt and check for wear or tension loss

Remove debris from loading zones and end-of-line cooling chambers

Signs Your Furnace May Need Immediate Attention

Sometimes even with routine maintenance, issues can arise. Address these warning signs immediately:

Irregular temperature profiles or slow heat-up time

Vacuum levels not reaching expected range

Frequent leakage of atmosphere gases or unexpected pressure drops

Unusual odors, noises, or visible arcing

Discoloration or inconsistent joint quality in brazed parts

Timely intervention prevents long-term damage and production losses.

Best Practices for Furnace Operators

Always follow the manufacturer’s maintenance schedule and guidelines

Maintain a detailed logbook documenting each maintenance activity and observed issue

Train furnace operators on basic troubleshooting and safety procedures

Keep spare parts (like thermocouples, gaskets, and filters) in stock to reduce downtime

Store cleaning tools and equipment near the furnace but away from direct heat or contamination sources

Partnering with the Right Brazing Furnace Manufacturer

Even the best maintenance routines are more effective when paired with quality equipment. That’s why choosing a reliable furnace manufacturer is essential. At www.hengdabrazingfurnace.com, you’ll find high-quality brazing furnace systems designed for longevity, ease of maintenance, and operational safety.

HENGDA’s equipment features robust construction, advanced atmosphere control systems, energy-efficient heating elements, and intelligent automation. They also provide:

Technical documentation and manuals

Preventive maintenance kits

Remote diagnostics and service

Global customer support and spare parts delivery

Their expertise ensures your brazing furnace stays in top condition throughout its operational life.

Conclusion

Maintaining and cleaning your brazing furnace is not just a good practice—it is essential for ensuring consistent brazing quality, operational safety, and return on investment. With daily checks, weekly inspections, and annual servicing, you can significantly extend the life of your furnace and prevent unplanned downtime or costly repairs.

A well-maintained brazing furnace will continue to deliver precision metal joining, energy efficiency, and high production reliability for years to come.

To explore maintenance-friendly brazing furnaces or schedule professional servicing, visit www.hengdabrazingfurnace.com and let the experts help you keep your operations running smoothly.