In the ever - evolving realm of industrial manufacturing, brazing furnaces stand as indispensable assets, tasked with the critical function of joining materials to exacting standards of precision and durability. However, traditional electric heating brazing furnaces, once the mainstay of the industry, now grapple with a multitude of constraints in cost - effectiveness, operational efficiency, and environmental compliance. Hengda Furnace Industry Co., Ltd., with its groundbreaking NB Continuous Gas Brazing Furnace, emerges as a transformative force, leveraging natural gas as a heat source to redefine the boundaries of what is possible in this field.

Current Industry Landscape and Challenges

The demand for brazing equipment in contemporary industrial production continues to surge, fueled by the relentless pursuit of high - quality material joining across diverse sectors, including automotive manufacturing, electronics, aerospace, and beyond. Traditional electric heating brazing furnaces, which have long held a dominant position in the market, are now confronted with a series of formidable challenges.

From a financial perspective, electric heating systems are burdened with exorbitant energy consumption costs. The ceaseless operation of these furnaces results in astronomical electricity bills, significantly inflating production expenses. For small and medium - sized enterprises (SMEs) in particular, these elevated costs pose a substantial barrier to competitiveness, squeezing profit margins and limiting growth opportunities. Moreover, the inefficiency of electric heating extends beyond mere cost implications. Slow heating rates and imprecise temperature control are common drawbacks, often leading to extended production cycles. The inability to rapidly reach and maintain the optimal brazing temperatures not only hampers productivity but also compromises the consistency and quality of the final product. In industries where precision is paramount, such as electronics manufacturing, these limitations can have far - reaching consequences, resulting in higher defect rates and increased rework.

In an era defined by a global imperative for environmental sustainability, the environmental footprint of electric heating brazing furnaces has become a major concern. The carbon emissions associated with electricity generation, especially from fossil - fuel - based power sources, contribute significantly to greenhouse gas emissions. As governments worldwide implement stringent environmental regulations and businesses face growing pressure from consumers and stakeholders to adopt greener practices, companies relying on electric heating brazing furnaces find themselves at a crossroads, urgently needing to seek more sustainable alternatives.

Technical Analysis of the NB Continuous Gas Brazing Furnace

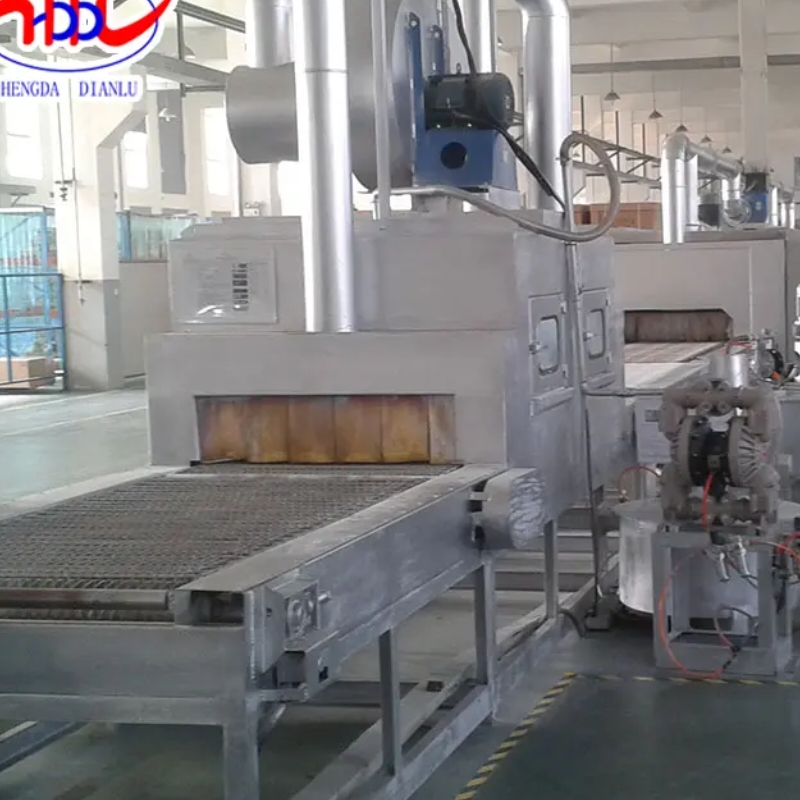

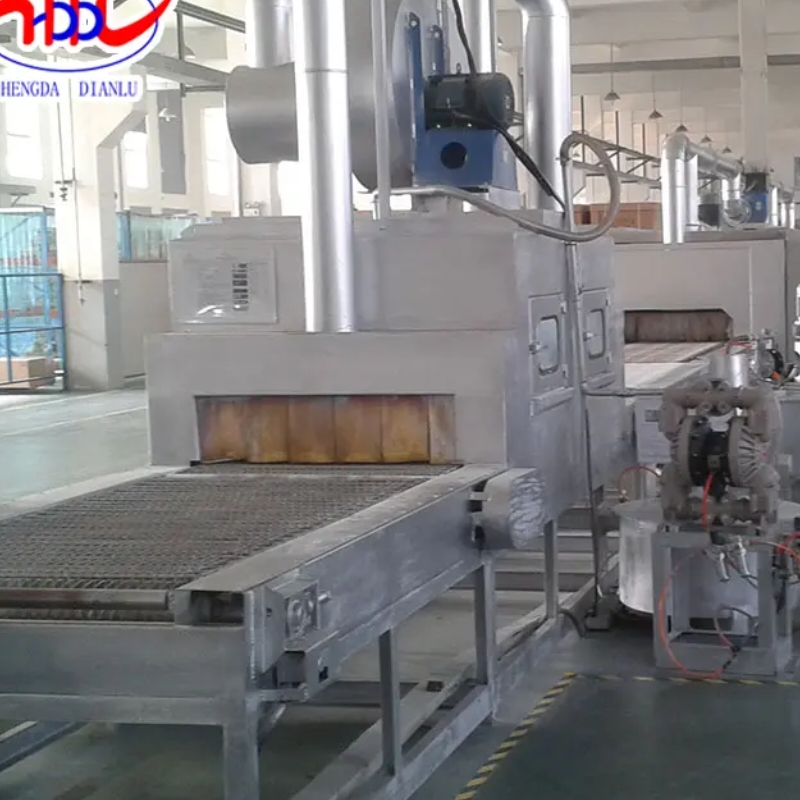

The NB Continuous Gas Brazing Furnace developed by Hengda Furnace Industry Co., Ltd. represents a remarkable technological advancement, with natural gas as its cornerstone heat source. At the heart of this innovative furnace lies a sophisticated combustion mechanism. Natural gas, renowned for its clean - burning properties and high energy density, is precisely metered and mixed with air within the combustion chamber. This meticulous mixing process ensures complete and efficient combustion, generating a powerful, stable, and consistent heat source that forms the basis for superior brazing performance.

One of the most notable technological breakthroughs of the NB Continuous Gas Brazing Furnace is its intelligent combustion system. Equipped with state - of - the - art sensors and control algorithms, this system continuously monitors and adjusts the gas - air ratio in real - time. By dynamically adapting to changing production requirements, such as variations in the size, shape, and material of the components being brazed, it maximizes combustion efficiency and heat output. This not only reduces fuel consumption but also enhances the overall performance of the furnace, ensuring that it operates at peak efficiency under a wide range of operating conditions.

Complementing the intelligent combustion system is the furnace's advanced temperature control system. Utilizing high - precision temperature sensors and sophisticated PID (Proportional - Integral - Derivative) control algorithms, the NB Continuous Gas Brazing Furnace can achieve rapid heating, reaching the desired brazing temperature in a fraction of the time compared to traditional electric heating models. The temperature control accuracy is astonishing, with a tolerance of within ±X℃. This level of precision is critical for achieving high - quality brazed joints, as even the slightest temperature deviation can affect the metallurgical properties of the joint, leading to reduced strength and durability.

Safety is of paramount importance in the design of the NB Continuous Gas Brazing Furnace. The furnace is equipped with an array of comprehensive safety features to safeguard both the equipment and the operators. Multiple layers of explosion - proof devices are integrated into the structure, designed to withstand extreme pressure conditions in the unlikely event of an ignition. Gas leakage monitoring sensors are strategically placed throughout the system, capable of detecting even the smallest gas leaks in real - time. Upon detection, an immediate alarm is triggered, and the gas supply is automatically shut off, preventing the risk of fire or explosion. Additionally, the furnace is equipped with emergency stop buttons, allowing operators to quickly halt the operation in case of any unforeseen circumstances.

The NB Continuous Gas Brazing Furnace is highly versatile and adaptable to a wide range of industrial applications. In the automotive industry, it plays a crucial role in the production of engine components, exhaust systems, and body structures. The ability to achieve precise and consistent brazing temperatures ensures strong and reliable joints, enhancing the overall performance and safety of the vehicle. In the electronics sector, where the components are often delicate and require extremely precise brazing, the furnace's high - precision temperature control and rapid heating capabilities make it an ideal choice. It enables the production of high - quality electronic devices with improved reliability and longer lifespan. In the aerospace industry, where the quality and durability of brazed joints are non - negotiable, the NB Continuous Gas Brazing Furnace provides a reliable and efficient solution, meeting the stringent requirements of this demanding sector.

Hengda Furnace Industry Co., Ltd.'s Strengths

Hengda Furnace Industry Co., Ltd. has firmly established itself as a leader in the furnace manufacturing industry through decades of unwavering dedication to research, development, and innovation. The company's brand is built on a solid foundation of technical excellence, product quality, and customer satisfaction. With a team of highly skilled engineers, researchers, and technicians, Hengda continuously invests in cutting - edge technologies and innovative solutions, driving the evolution of furnace manufacturing.

The company's research and development (R&D) system is a well - oiled machine, characterized by a culture of collaboration and a commitment to excellence. Hengda has forged strong partnerships with leading academic institutions, research centers, and industry experts around the world. These collaborations enable the company to stay at the forefront of technological advancements, leveraging the latest research findings and expertise to develop innovative products. As a result, Hengda has amassed an impressive portfolio of patented technologies, many of which are incorporated into the design and manufacturing of the NB Continuous Gas Brazing Furnace. These patented technologies not only enhance the performance and functionality of the furnace but also provide a competitive edge in the market.

In addition to its R&D prowess, Hengda places a strong emphasis on quality control. The company's production facilities are equipped with state - of - the - art manufacturing equipment and adhere to strict international quality standards. Every stage of the production process, from raw material procurement to final assembly and testing, is subject to rigorous quality inspections. This meticulous approach ensures that each NB Continuous Gas Brazing Furnace leaving the factory meets the highest standards of quality, reliability, and performance. Hengda's commitment to quality has been recognized by numerous international certifications, further validating the company's position as a trusted provider of industrial furnaces.

Conclusion

In conclusion, the NB Continuous Gas Brazing Furnace from Hengda Furnace Industry Co., Ltd. represents a paradigm shift in the field of industrial brazing. With its innovative use of natural gas as a heat source, advanced technical features, and the backing of a reputable and experienced manufacturer, it effectively overcomes the limitations of traditional electric heating brazing furnaces. Whether you are a manufacturer looking to improve your production efficiency, reduce costs, or enhance your environmental performance, the NB Continuous Gas Brazing Furnace offers a comprehensive solution. For more detailed information about this revolutionary product, including technical specifications, product brochures, and customized solutions, please visit our official website at www.hengdabrazingfurnace.com.Our team of experts is ready to assist you in finding the perfect furnace to meet your specific needs and requirements.